Watch The Video:

Read The Story:

For Michal and her husband, designing staircases and hand-rails became an important part of redeveloping their home in Golders Green, north-west London.

“One of the first things visitors comment on is the staircase,” said Michal.

As a five-storey building, staircases play a big part in both the house’s function and visual impact, and Michal was striving for nothing less than perfection with each of her four new staircases.

“Everything is new and the four staircases are something that we actually spent a lot of time thinking about their look and feel,” said Michal. “We think it’s really a very big part of the design of the house is the staircase.”

Arc Fabrications Provided The Essential Creative Process

It was important for Michal that she found a company she could work with to help her turn an idea into reality. The creative process was essential for her.

“I think what I loved about Arc Fabrications is that the creativity process was there.”

“The only thing I had in mind is what the feel that I wanted to have,” said Michal. “After that I just had to speak with Steve and the guys at Arc Fabrications, to see what I’m I was after and what I’d like to achieve.

“But I kind of shared what I’m passionate about and then we got together and just came up with different ideas. They were very open to testing colours and materials and looks and feels and we were just – it was very creative. The whole process was creative.

“I really enjoyed and loved the way that Arc Fabrications approached my query just even from the initial phone call. I told them that I know with the feel that I want to achieve and what the house is all about, and kind of the narrative of the house, and that I’d like a mix of different materials but I don’t know exactly what it looks like. I don’t I don’t have a picture to tell them, ‘This is exactly what I want’.

“I think what I loved about Arc Fabrications is that the creativity process was there.”

It’s that focus on delivering what the customer truly wants that sets Arc Fabrications apart from its competitors.

(And it’s so easy to start the process with Arc for your next project, just by requesting a quote using the online form.)

“We contacted a few companies at the same time, when we contacted Arc Fabrications,” said Michal. “They weren’t interested in designing something from us. They were more about, like, ‘We have these four, five, six staircases that are more popular and quite contemporary, do you want those?’ – and when I wanted to make some changes, I didn’t feel an appetite for the creativity.”

Got a fabrication project?

Other Companies Charge For Expensive 3D Drawings

Michal did find some creativity from the other possible metal fabrications companies – they wanted to charge a lot of money for 3D CAD drawings of staircase designs.

At Arc Fabrications, staircase designs usually start on paper. So with a customer like Michal, she could immediately see a sketch, without paying for computer-aided drawings. And that’s even more important when you’re designing four different metal staircases for your home, like Michal was.

“It’s one of the other things I loved about working with Arc Fabrications, she said. “Some companies have those 3D, ‘Tell me what you want and we’ll put it together and we’ll show you.’

“I didn’t have a good experience with that at all because they asked for a ton of money to do that, for different illustrations, before even you think about maybe doing it with that company.

“And also what I like about Arc Fabrications is when you go into the workshop or when you communicate with them it feels very real. It’s not a massive business, but then it runs like a very strong very well-managed business.”

Whatever size project the company undertakes, owner Steve Gibbs has never lost sight of the importance of taking care of his customers.

“The result is top-end… without top-end London prices.”

“Whether it’s installing handrails for a disabled person in local authority housing, or replacing railings at a foreign embassy in central London, I always want us to do the best we possibly can for our customers, ” said Steve.

The difference for customers like Michal is clear.

“You get the benefit from like a medium-small size business,” said Michal, “but the result that you get is from like top-end, in my opinion so you enjoy both worlds.

“On cost, they’re fair,” she said. “Maybe they’re not the kind of lowest, cheapest but I wouldn’t want to go that level. But they’re also not that kind of top London prices that I was quoted for. So I think it’s a very very good offer and very balanced from from the cost perspective.

Highly Recommended

“I’ve already referred three friends to Arc Fabrications,” said Michal. She tells them about how Arc isn’t the typical company that wants to sell something off-the-shelf, but instead help design and build whatever you want.

“‘You want something different?’ If you want an ordinary staircase – none of my friends are looking to kind of design ordinary more – you know – I don’t want to say ordinary, it sounds judgmental – but more kind of classic houses then I probably – I wouldn’t say, you know maybe you don’t have to invest in this.“I would say, ‘Work with Arc Fabrications’ for sure.”

“But anyone that wants a more contemporary, bespoke, unique staircase, where they can really put their own kind of signature and make it feel – make the house feel something different through the staircase, I would say, ‘Work with Arc Fabrications’ for sure.”

“And I know someone can think, ‘Well oh it’s only a staircase'” said Michal. “But actually most people that come to our house, one of the first things that they comment about is the staircase. And I didn’t want it to be an ordinary staircase, so. I think the value for money is there for sure.

“I also think about, like it’s not it’s not a wooden. I don’t think that ordinary would create wooden staircase. So think about like just the materials that they work with are expensive. Just the metal the mesh, the, you know, the combining of them together like that takes a lot of time. It has to be perfect.“

“When people come to the house, the first thing they comment on is the staircase.”

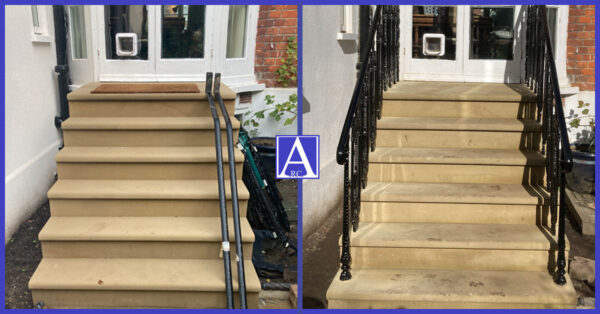

“We started with what is, at least for us, a simple, basic staircase,” explained Steve Gibbs, the owner of Arc Fabrications. “However, since no other company would offer this particular combination for Michal, to her, it was very bespoke.

“The stringers were made from 200mm x 8mm flat steel bars, the tread plates were also 250mm x 8mm flat steel, which Michal had topped with a timber covering.

“The hand-rails were made from unequal box-section framework, fitted with welded lugs to hold the mesh panel inserts, cut-to-size and edged with u-section trim – which ensured the kids fingers stayed safe while giving a neat finish.

“The hand-rails were made from unequal box-section framework, fitted with welded lugs to hold the mesh panel inserts, cut-to-size and edged with u-section trim – which ensured the kids fingers stayed safe while giving a neat finish.

“Where Michal added glass inserts instead of mesh, we fabricated the framework and lugs, identical to the mesh sections, and then her glazier created templates in order to custom-cut the glass to fit.

“Everything was undercoated in the workshop, and then painted with a top-coat on-site, using specific colours picked by Michal.

“We’ve made many staircases for big buildings before, like blocks of flats and big period house in central London,” said Steve. “But this was the first time we’ve created four separate staircases for a single house. It was quite a project, very interesting, and a pleasure to work with people who truly appreciate the service we provide.”

Despite the time taken by the whole development project, Michal has no hesitations in doing it all over again.

“Of course I would do it again!”

And the staircase?

“And the staircase! I would do it again!” said Michal.

“I love it it’s so creative. It’s so much fun.”